See It In Action ...

Premier Gas Chromatograph

Keeping the analyst in mind, Shimadzu’s Nexis GC-2030 gas chromatograph offers the most versatile, sensitive, and reproducible research-level unit on the market. Coming with included innovative features like ClickTek tool-free maintenance and our in-oven light, a variety of inlets and detectors to choose from like the SCD-2030, and the systems capability to be used in our Application Specific System GC program will elevate your lab to the next level. This GC is the nexus between receiving samples and answering questions whether in the petrochemical, environmental, food, forensics, or other industries.

Designed with the Analyst in Mind

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt

Intuitive

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt

Multi-functional:

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt

Multi-functional:

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt

Fast

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt

Intuitive

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt

Multi-functional:

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt

Multi-functional:

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt

| Test Color | Test Color White |

| Test Spec | Test Option 2 |

Various Content Block Options

Heading 3

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type."

Heading 3

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type."

Heading 3

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type."

Heading 3

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type."

Heading 3

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type."

Heading 3

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type."

Heading 3 here

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type."

Heading 3 here

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type."

BODY CONTENT - Praesent nunc purus euismod feugiat eros ante. Sagittis mi ultrices, lacinia dolor turpis lorem ut. Nisi netus ac ut volutpat gravida rhoncus urna urna. Tristique nulla quam pretium hendrerit eros tempus pharetra. Urna curabitur rutrum dui; cursus accumsan vel. Nisi placerat nam integer neque tristique nibh penatibus. Diam lacinia nec eleifend vitae dapibus consectetur consequat euismod iaculis. Turpis pellentesque vel efficitur metus scelerisque sociosqu. Netus vivamus mus vivamus morbi sociosqu quisque. Feugiat vivamus tellus taciti scelerisque fringilla pharetra leo faucibus ornare. Potenti justo finibus sapien congue velit. Sit quisque odio; efficitur justo natoque egestas. Adipiscing turpis facilisis congue et habitant himenaeos pulvinar. Massa ex sodales dictum cubilia dignissim vestibulum ultricies ipsum. Quis ultrices consectetur aliquet conubia magnis nam cras phasellus. Dis primis nam at condimentum odio, ornare suscipit tempor.

Eu condimentum tortor tempor in ac, sodales varius ultricies. Eleifend lorem congue eros pretium; placerat enim. Maximus litora dignissim quam nam, iaculis eu. Nulla luctus ac feugiat class pellentesque sit felis. Facilisi natoque dictum suspendisse donec pharetra facilisis laoreet. Leo elit vitae varius accumsan parturient. Ad blandit risus aliquet nisl tortor nullam magnis. Et aptent venenatis iaculis tortor sapien luctus erat praesent. Rutrum condimentum egestas pretium nam at vel bibendum. Tortor dignissim donec class vitae mauris ornare. Ut velit euismod fringilla nec ultricies viverra ac vestibulum. Porttitor at pretium augue non tempor mauris.

Risus libero platea phasellus tristique commodo ipsum vivamus felis. Nisl conubia volutpat velit a ex sit arcu. Justo ante faucibus congue ligula posuere? Hac hendrerit posuere tellus odio rutrum natoque sodales elementum. Ut egestas pulvinar ut, eget etiam aenean aliquam. Adipiscing platea elementum adipiscing felis eget sem eu ultricies. Dictum aliquet ipsum ultricies primis libero auctor. Suscipit ac pretium; primis aliquet habitasse pharetra.

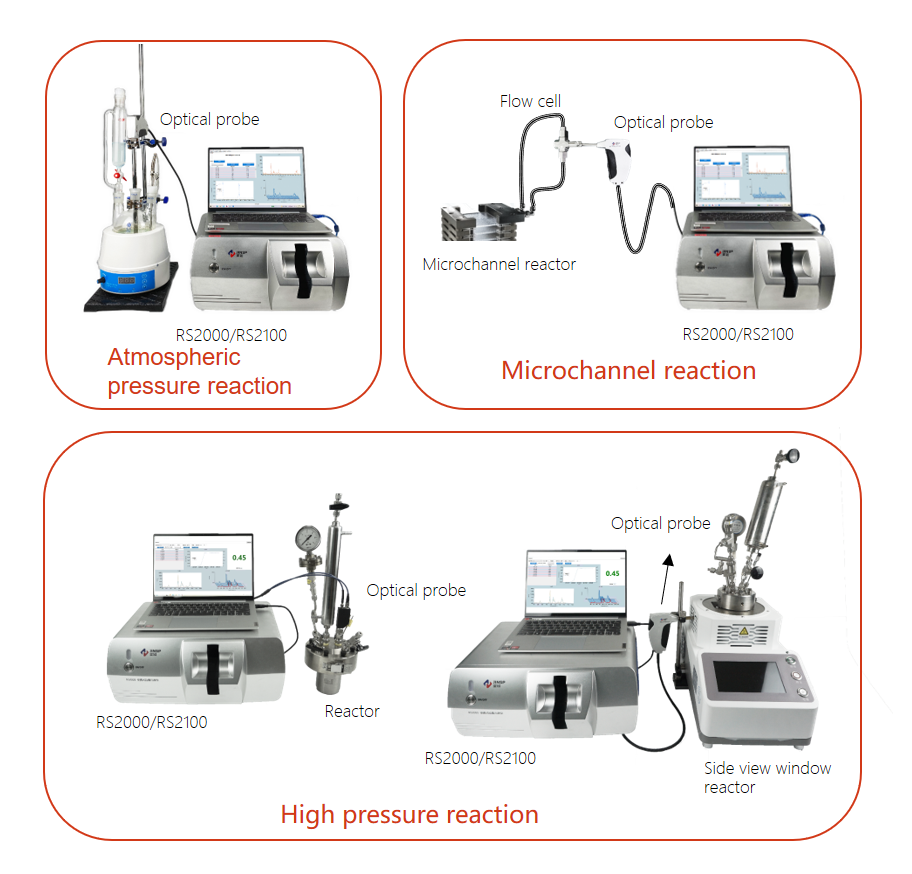

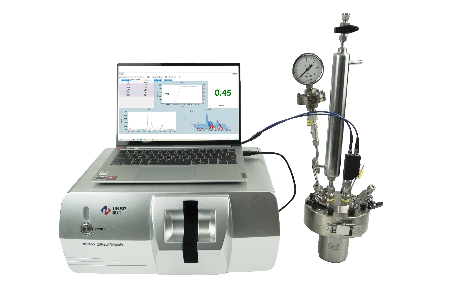

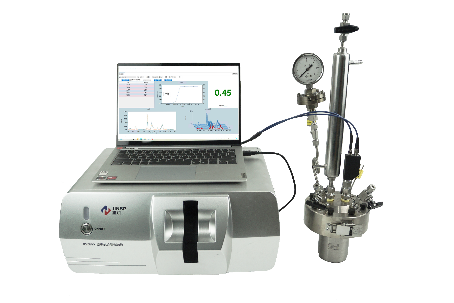

RS2000/RS2100 has three usage modes in the laboratory, and each mode requires different accessories.

1. The first mode uses an immersed long probe that goes deep down to the liquid level of the reaction system to monitor each reaction component. Depending on the reaction vessel, reaction conditions, and system, different specifications of probes are configured.

2. The second mode involves using a flow cell to connect a bypass probe for online monitoring, which is suitable for reactors like microchannel reactors. Various probes are configured based on the specific reaction vessel and conditions.

3. The third mode utilizes an optical probe directly aligned with the side window of the reaction vessel for reaction monitoring.

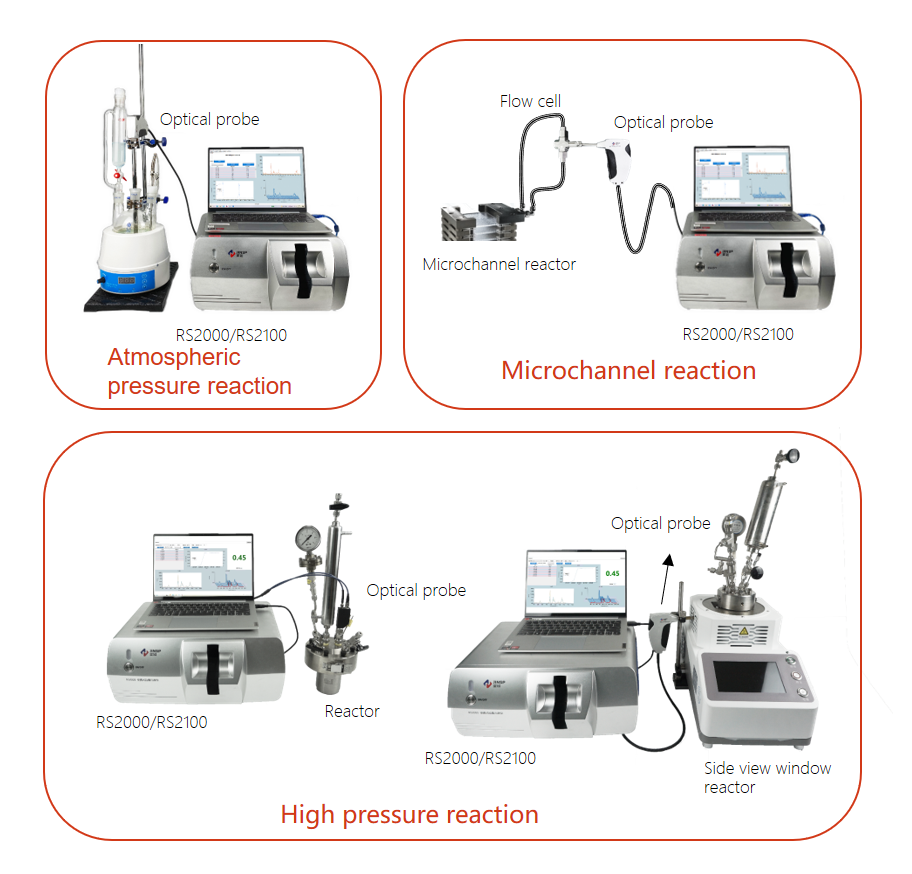

RS2000/RS2100 has three usage modes in the laboratory, and each mode requires different accessories.

1. The first mode uses an immersed long probe that goes deep down to the liquid level of the reaction system to monitor each reaction component. Depending on the reaction vessel, reaction conditions, and system, different specifications of probes are configured.

2. The second mode involves using a flow cell to connect a bypass probe for online monitoring, which is suitable for reactors like microchannel reactors. Various probes are configured based on the specific reaction vessel and conditions.

3. The third mode utilizes an optical probe directly aligned with the side window of the reaction vessel for reaction monitoring.

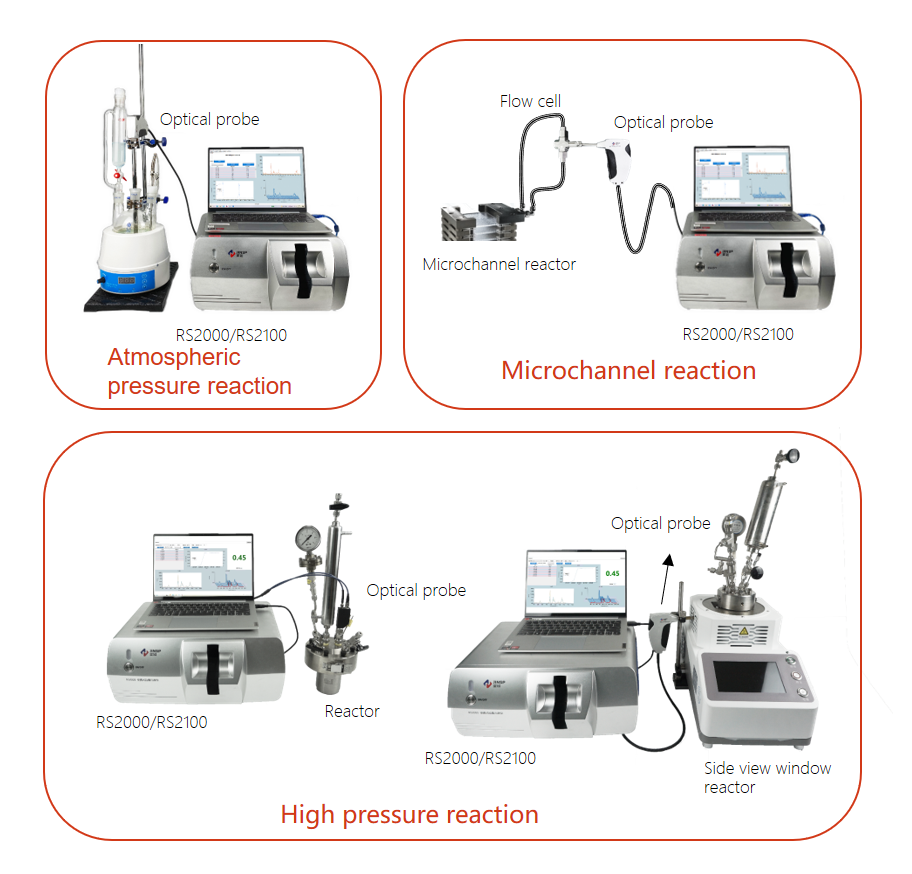

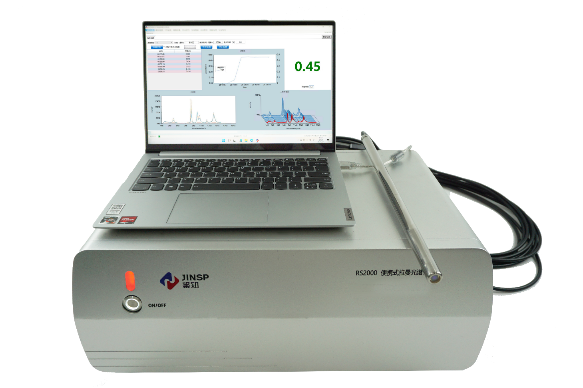

RS2000/RS2100 has three usage modes in the laboratory, and each mode requires different accessories.

1. The first mode uses an immersed long probe that goes deep down to the liquid level of the reaction system to monitor each reaction component. Depending on the reaction vessel, reaction conditions, and system, different specifications of probes are configured.

2. The second mode involves using a flow cell to connect a bypass probe for online monitoring, which is suitable for reactors like microchannel reactors. Various probes are configured based on the specific reaction vessel and conditions.

3. The third mode utilizes an optical probe directly aligned with the side window of the reaction vessel for reaction monitoring.

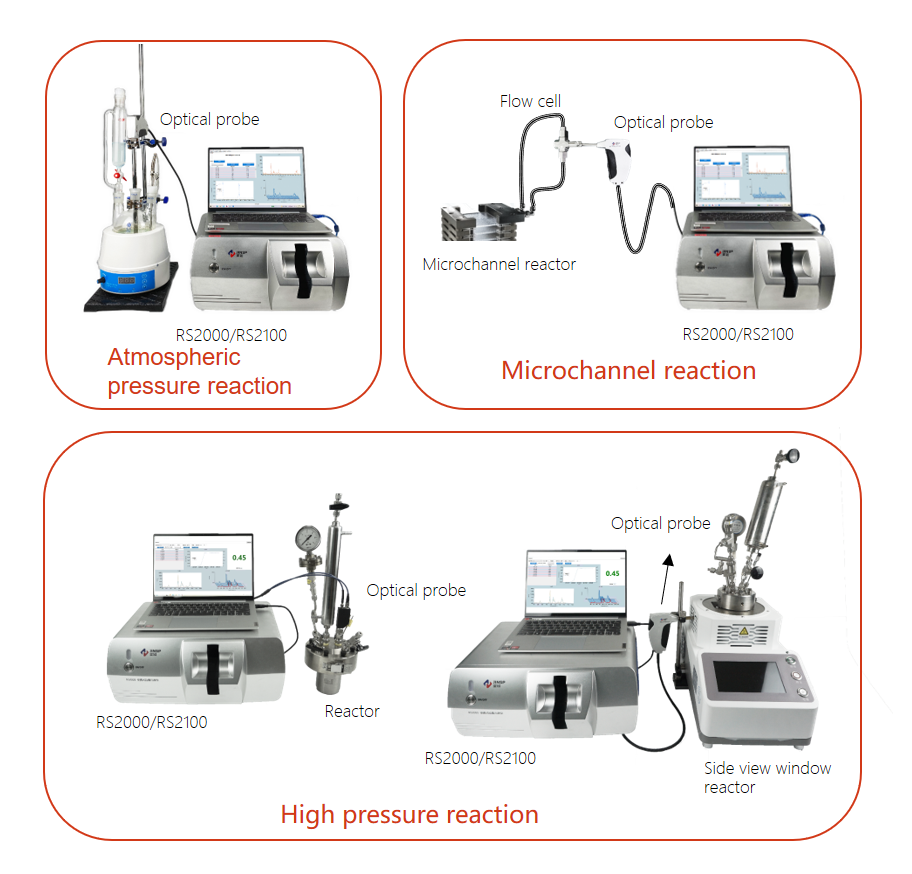

RS2000/RS2100 has three usage modes in the laboratory, and each mode requires different accessories.

1. The first mode uses an immersed long probe that goes deep down to the liquid level of the reaction system to monitor each reaction component. Depending on the reaction vessel, reaction conditions, and system, different specifications of probes are configured.

2. The second mode involves using a flow cell to connect a bypass probe for online monitoring, which is suitable for reactors like microchannel reactors. Various probes are configured based on the specific reaction vessel and conditions.

3. The third mode utilizes an optical probe directly aligned with the side window of the reaction vessel for reaction monitoring.

Product Specifications Version 1

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

| Specification | Details |

Content Block 2

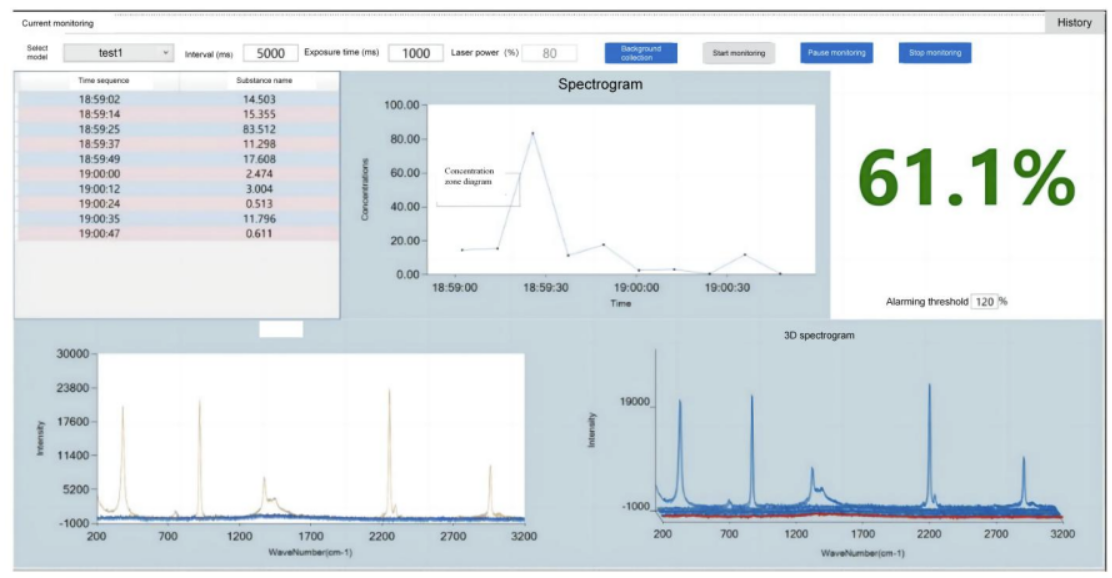

Online Monitoring

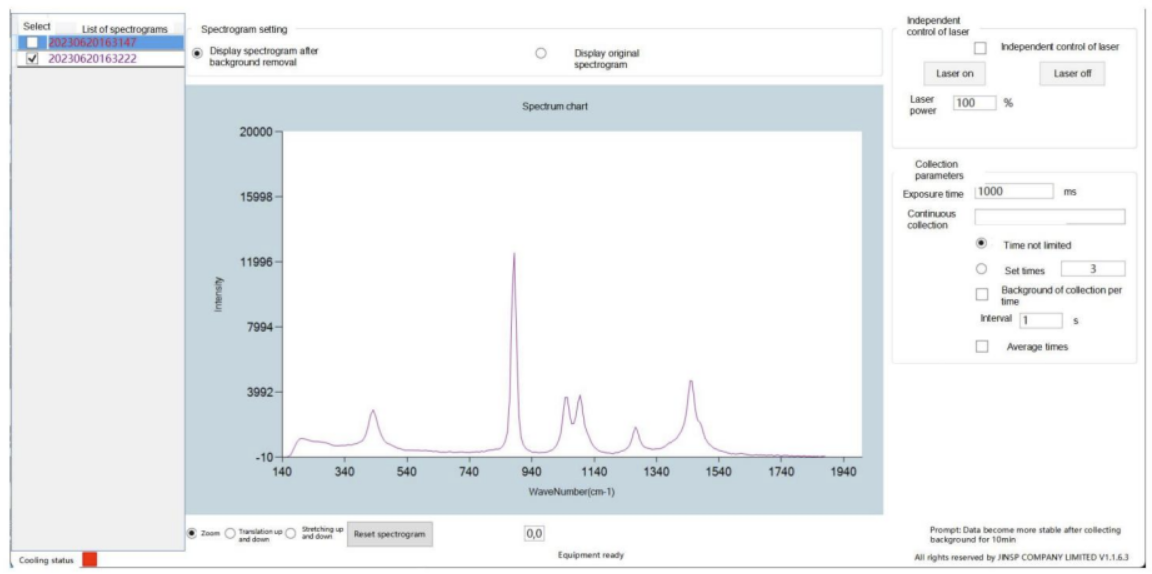

Data acquisition

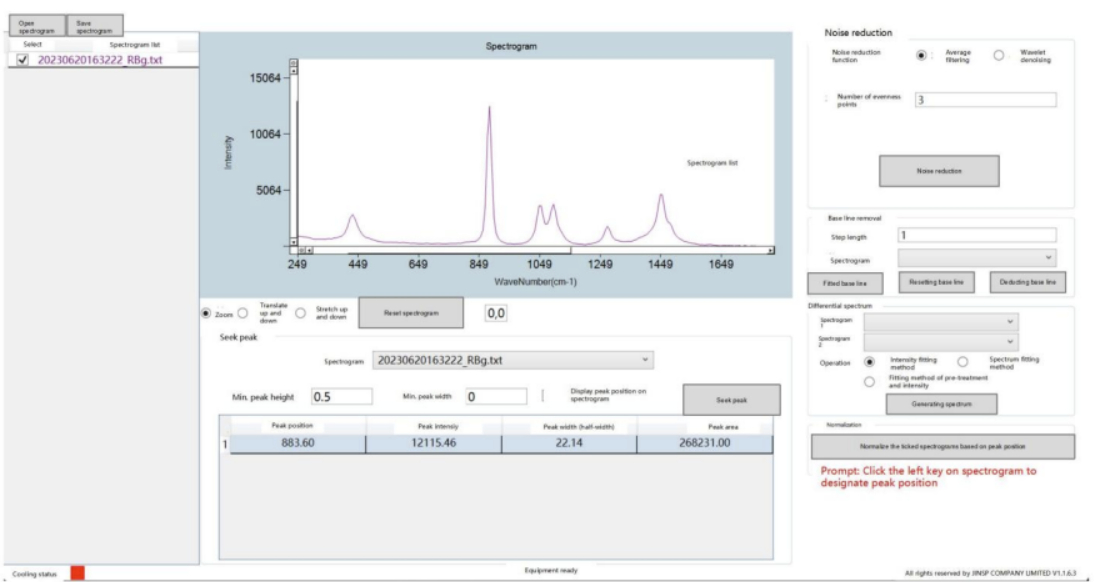

Data Processing

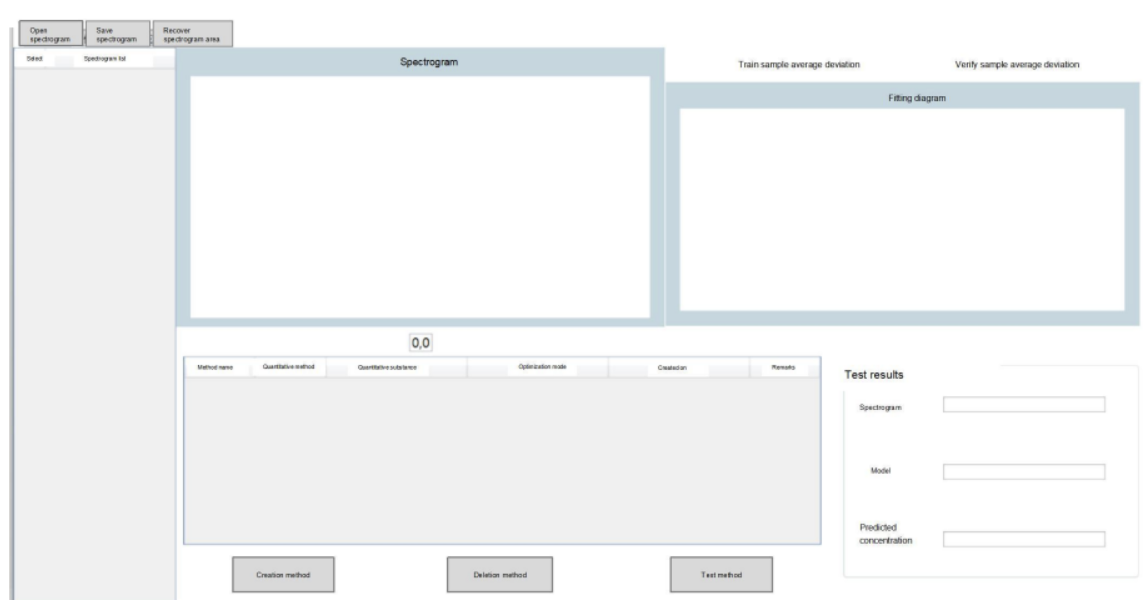

Research Methods

Data Processing

Research Methods

Li-ion battery industry:

Research on the synthesis process of bis(fluorosulfonyl)amide

Biopharmaceutical industry

Drug crystal form research and consistency evaluation

Quality Control in Biofermentation Engineering

Fine chemical industry News

Research on the process of producing furfuryl alcohol by hydrogenation reaction of furfural

Process control of bioenzyme catalytic reactions of nitrile compounds

A certain ultra-low temperature nitrification reaction

Research on o-xylene nitration reaction process

.... and more

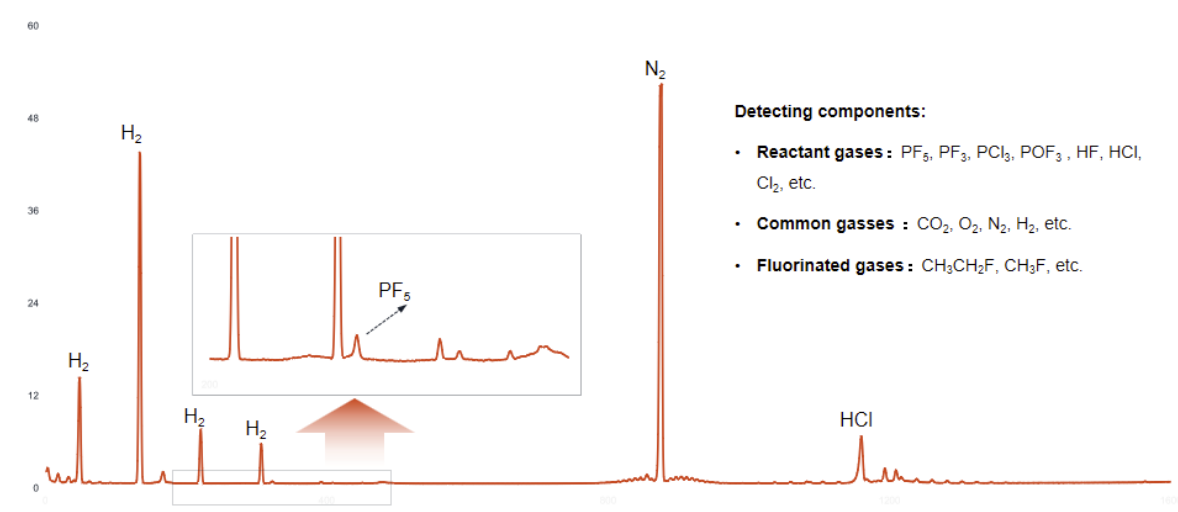

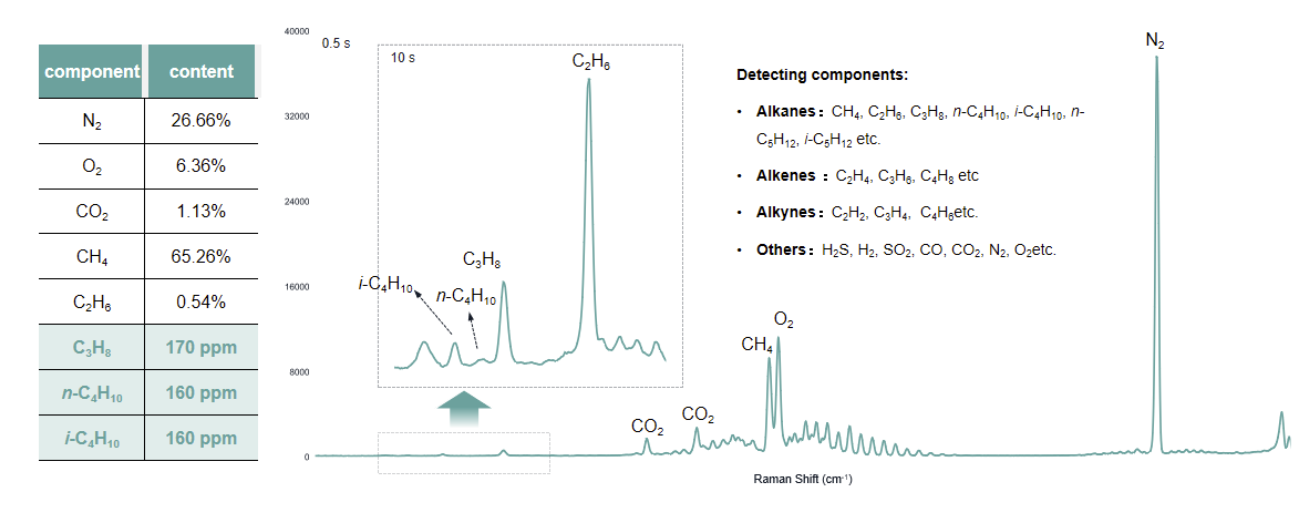

The RS2600 Multi-Gas Analyzer is ideal for various industries, including:

- Natural Gas Industry

- Metallurgical Industry

- Coal Chemical Industry

- Fluorine Chemical Industry

- Electronic Special Gas Industry

- Pharmaceutical Chemical Industry

Examples of Typical Applications

Detection of Components in Reaction and Emitted Gases of Fluorine Materials:

See More

Quantitative Analysis of Different Elements in Petrochemical Natural Gas:

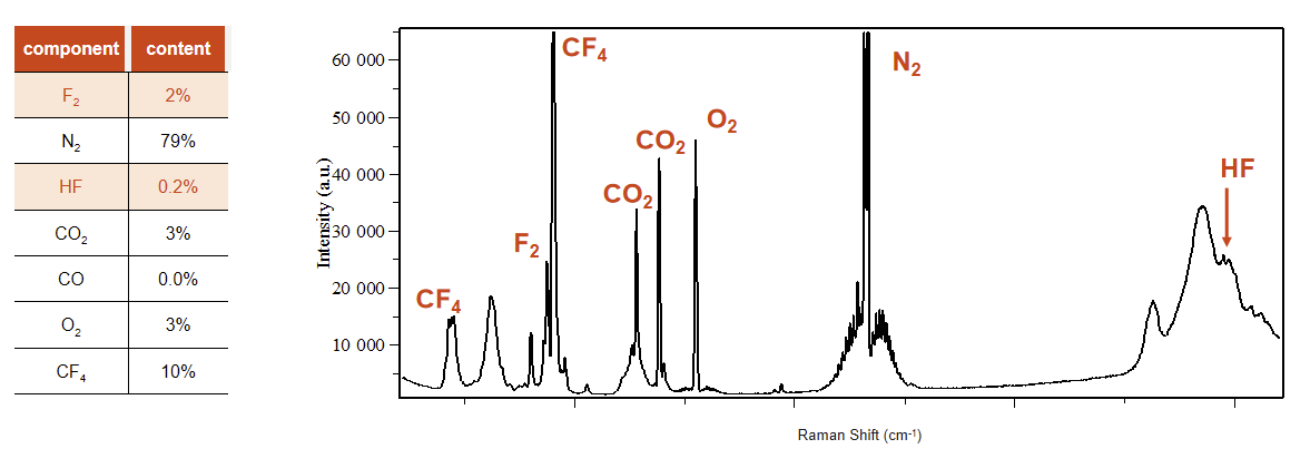

Monitoring of F2, N2, HF, and Other Components in the Fluorination Process:

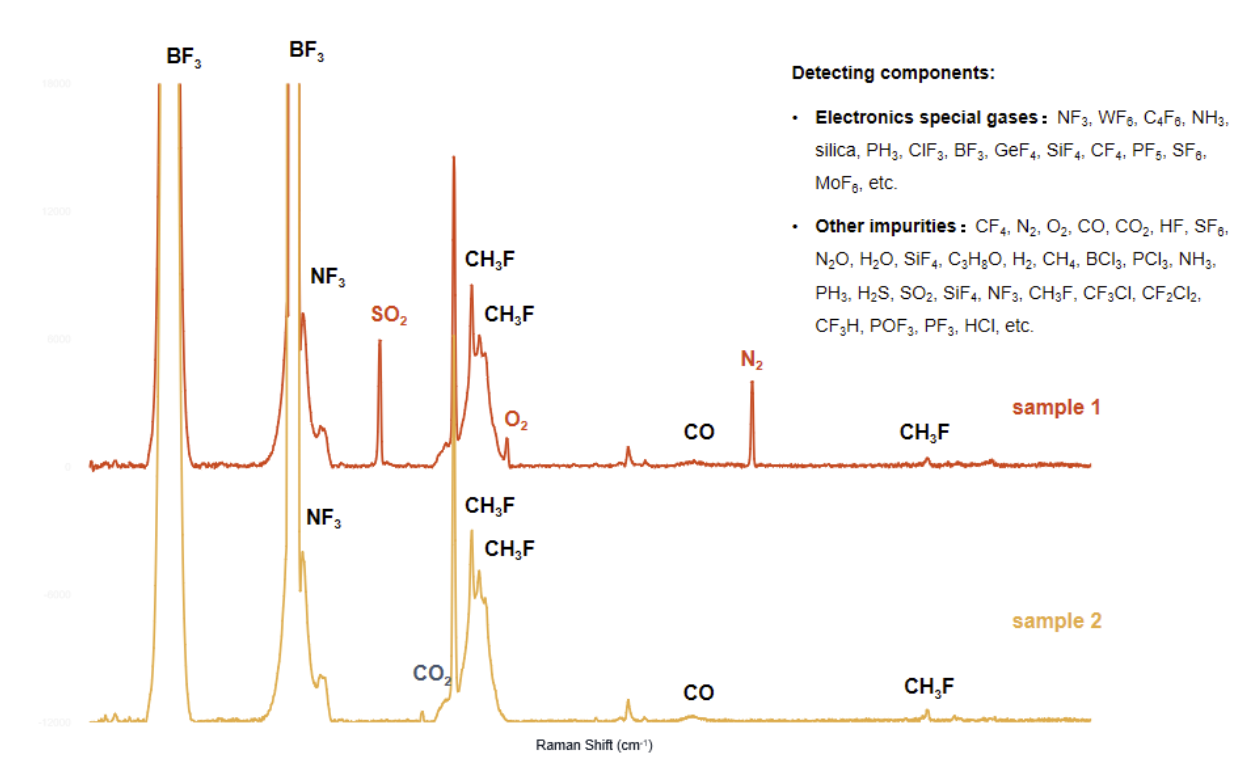

Detection of Impurity Gases in Electronic Special Gases:

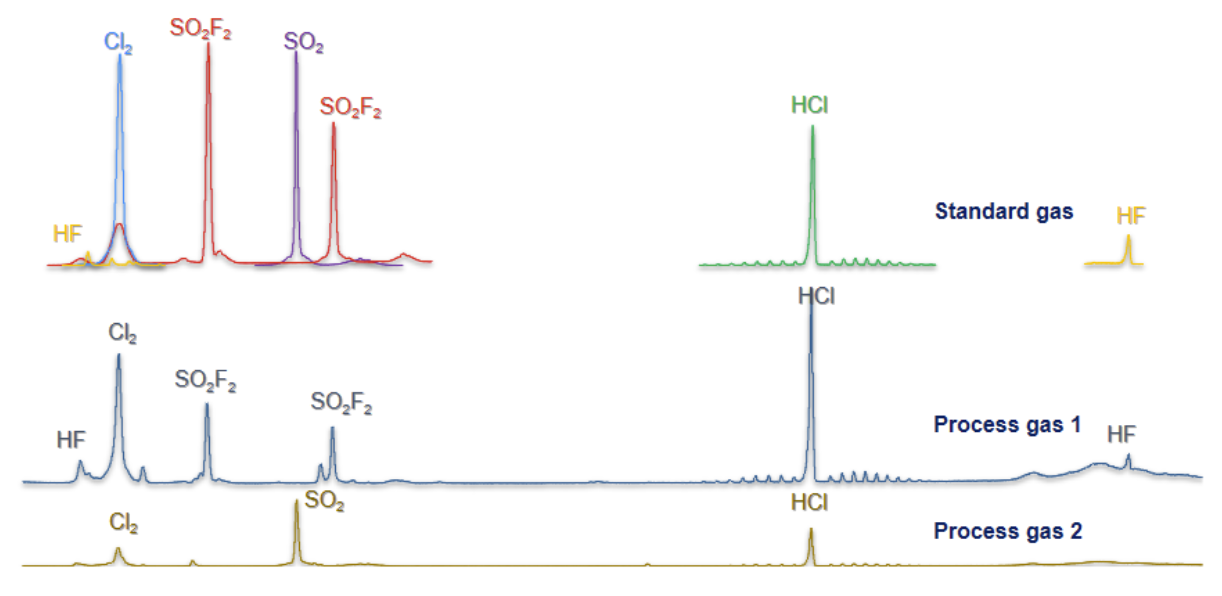

Monitoring of Gas Components in Sulfonyl Fluoride Synthesis:

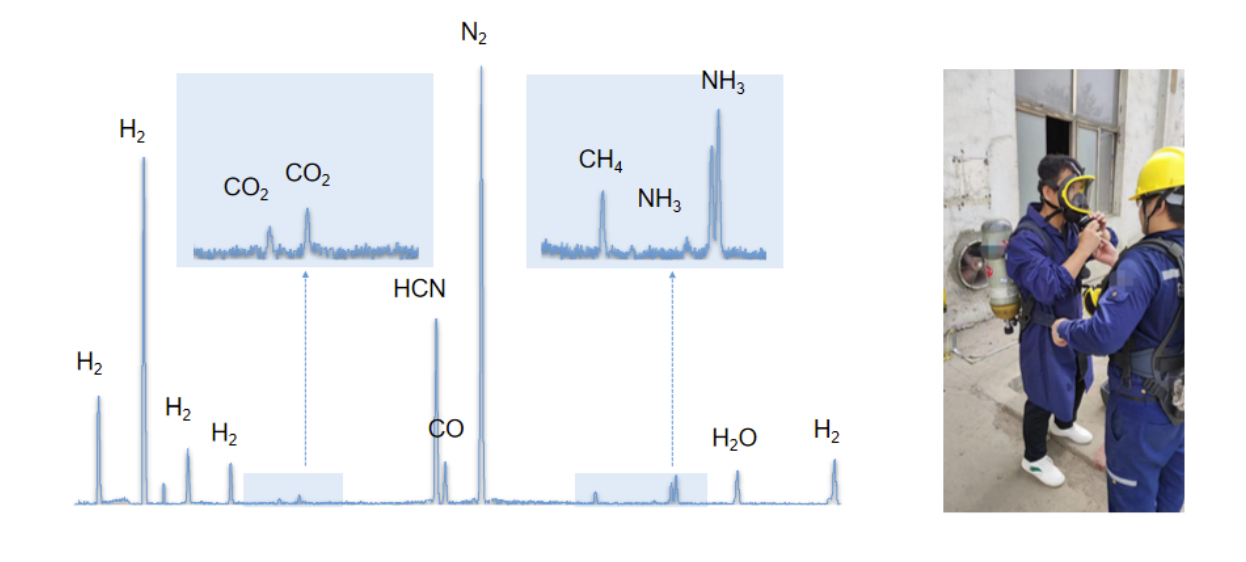

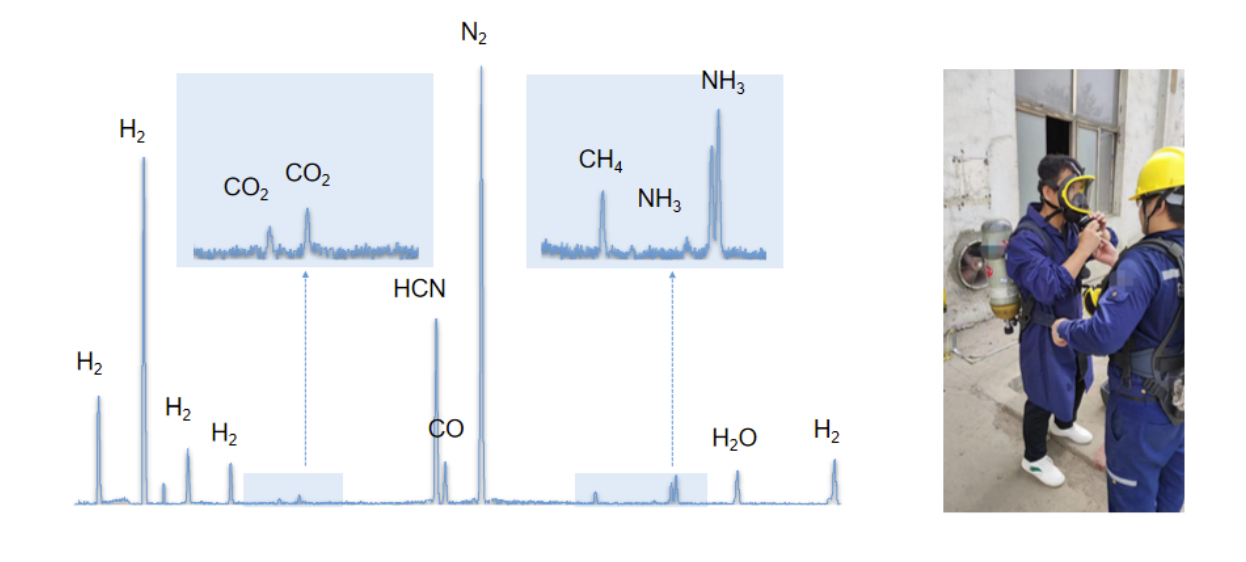

Remote Online Monitoring of HCN:

Diego

Related Products

|  |  | ||||

| Model | RS2000 | RS2000A | RS2000T | RS2000TA | RS2100 | RS2100H |

| Features | High sensitivity | Cost-effective | High sensitivity | Cost-effective | High applicability | High applicability, high sensitivity |

| Number of detection channels | 1, single channel | 1, single channel | 1, single channel | 1, single channel | 1, single channel | 1, single channel |

| Dimensions | 375 mm (width) × 360 mm (depth) × 185 mm (height) | 75 mm (width) × 360 mm (depth) × 185 mm (height) | 496 mm(width)× 312 mm(depth)× 185 mm(height) | 496 mm(width)× 312 mm(depth)× 185 mm(height) | 375 mm (width) × 360 mm (depth) × 185 mm (height) | 300 mm (width) × 356 mm (depth) × 185 mm (height) |

| Weight | ≤10 kg | |||||

| Probe | In standard configuration, one 1.3 m non-immersed fiber optic probe (PR100) and one 5 m immersed probe (PR200-HSGL), optional configurations include other probe models or flow cells. | |||||

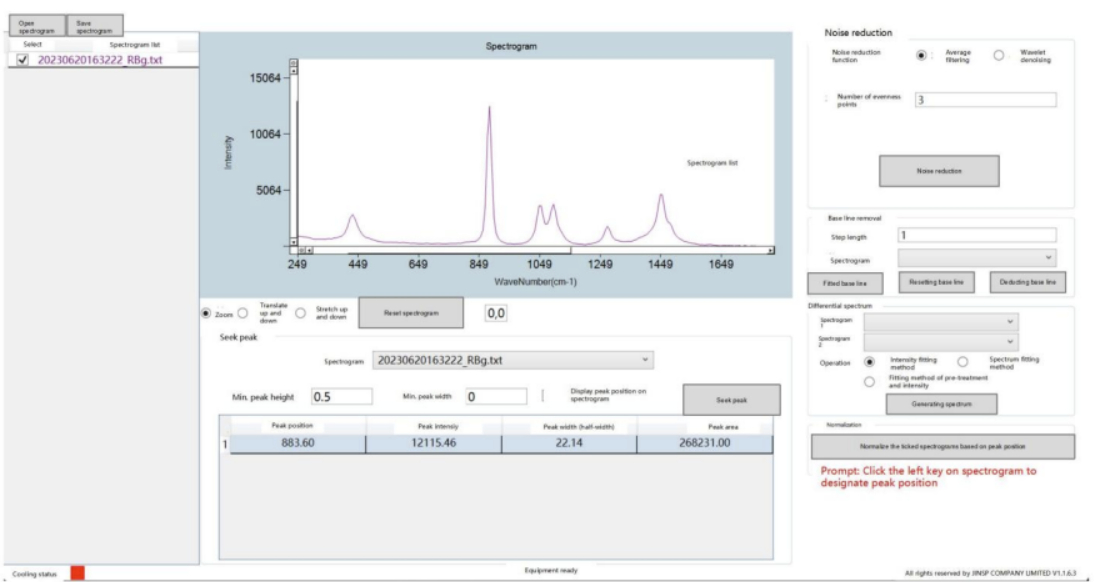

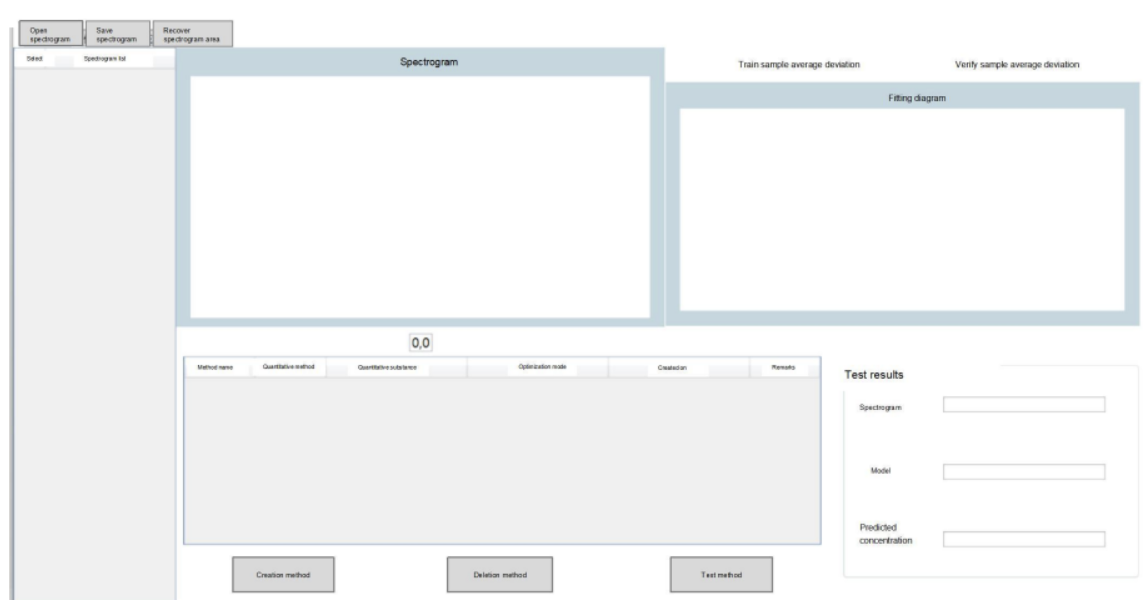

| Software features | 1.Online Monitoring: Continuous real-time collection of single-channel signals, providing real-time substance content and trend changes, enabling intelligent analysis of unknown components during the reaction process, 2.Data Analysis: Capable of processing data through smoothing, peak finding, noise reduction, baseline subtraction, difference spectra, etc, .3.Model Establishment: establishes a quantitative model using known content samples and automatically builds a quantitative model based on real-time data collected during the reaction process. | |||||

| Wavelength accuracy | 0.2 nm | |||||

| Wavelength stability | 0.01 nm | |||||

| Connectivity interface | USB 2.0 | |||||

| Output Data format | spc standard spectrum, prn, txt and other formats are optional | |||||

| Power supply | 100 ~ 240 VAC,50 ~ 60 Hz | |||||

| Operating temperature | 0 ~ 40 ℃ | |||||

| Storage temperature | -20 ~ 55 ℃ | |||||

| %Relative humidity | 0~90%RH | |||||

| Power consumption | 50 W | |||||

| Pre-heating time | <5 min | |||||

| Communication protocols | Modbus | |||||

Related Products

|  | ||||

| Model | RS1000 Handheld Raman Identifier | RS1500 Handheld Raman Identifier | |||

| Description | JINSP RS1000 handheld identifier is the new generation of handheld detection equipment designed for the identification of unknown materials. It is used to quickly identify drugs, precursor chemicals, dangerous liquids, explosives, jewelry, jade, industrial raw materials, etc. The device is compact and lightweight, weighing less than 500g, making it suitable for single-hand operation and easy portability. The built-in safety inspection module can detect the material without any variation, ensuring the detection of dark black material without ignition risk. It has a 5-inch high-sensitive touch screen with a built-in 13-million HD camera along with built-in WiFi, 4G, and Bluetooth transmission module, providing an intelligent operation experience. | JINSP RS1500 Handheld Raman Identifier uses Raman spectroscopy technology, combined with intelligent algorithms and rich spectrum library, to quickly and nondestructive identify suspicious materials at sites, such as chemical weapon, toxic, explosives, drugs and precursors, etc. The RS1500 directly gives the name and detailed information of the suspicious materials, helps operators quickly understand its characteristics. The RS1500 is applicable to customs supervision, drug prohibition, emergency management, national defense, etc. The RS1500 uses 1064nm laser, which can effectively reduce fluorescence interference. Therefore, the detection results are more accurate than those of the previous generation, which use 785nm or 830nm laser. | |||

| Attribute name | Attribute value |

|---|---|

| Test Color | Test Color White |

| Test Spec | Test Option 2 |