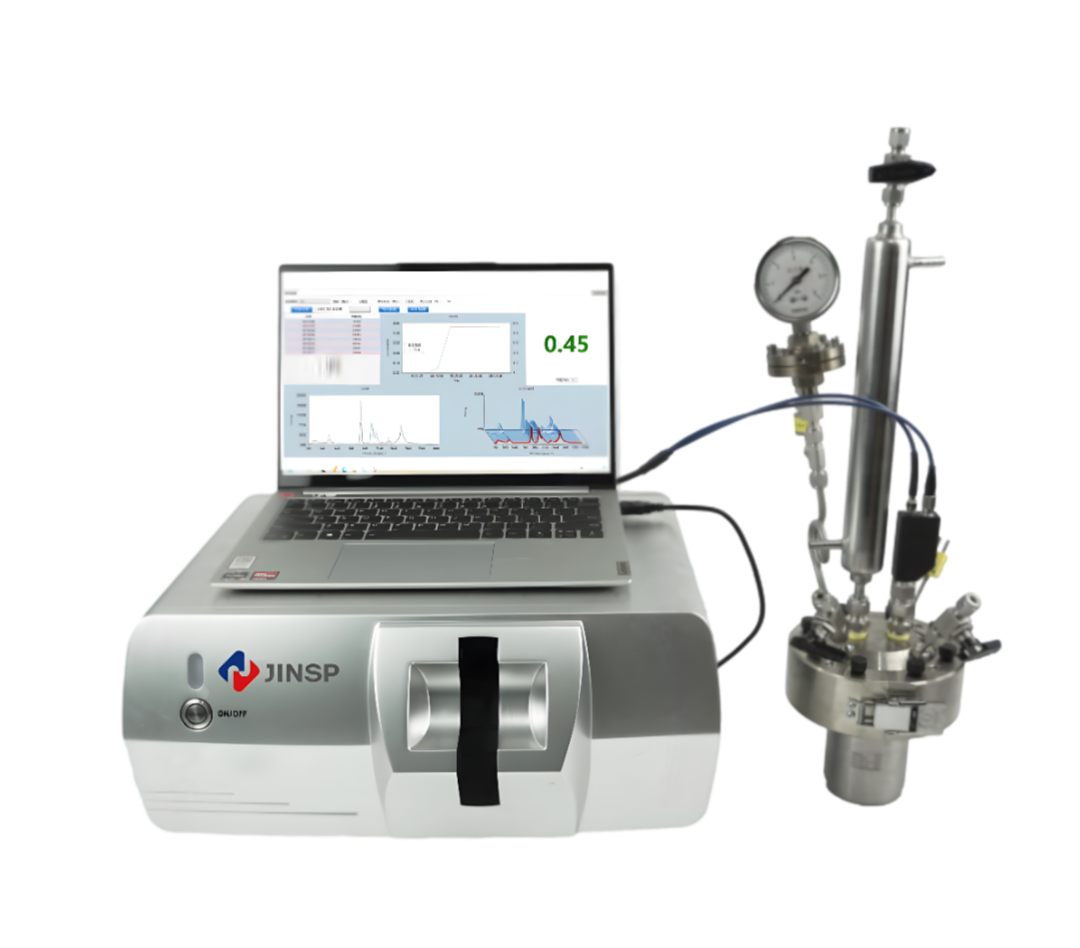

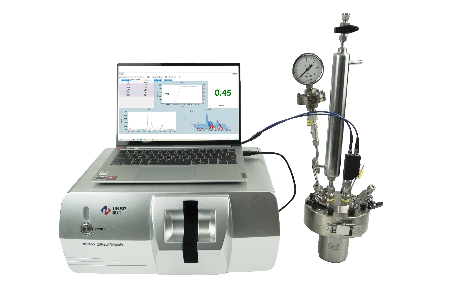

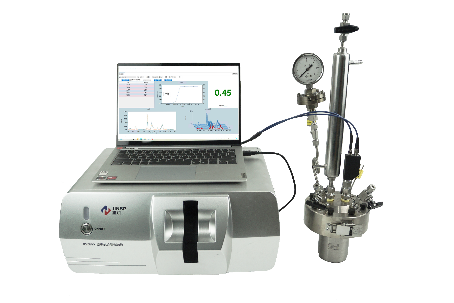

JINSP COMPANY LIMITED® RS2000 online Raman analyzer can be used for in-situ, real-time and continuous online monitoring of reaction. RS2000 has been used in the field of fine chemicals for reaction mechanism, kinetics, crystal form research, process development and optimization. In particular, it is applicable to dangerous processes such as nitration, chlorination, fluorination, hydrogenation, diazotization.

- Can withstand extreme reaction conditions such as strong acid, strong alkali, strong corrosiveness, high temperature, and high pressure.

- Real-time response in seconds, no need to wait, providing analysis results promptly.

- No sampling or sample processing required, in-situ monitoring without interference to the reaction system.

- Continuous monitoring to quickly determine the reaction endpoint and alert for any anomalies.

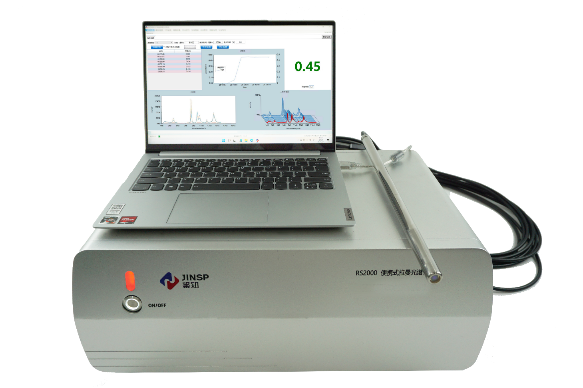

RS2000 Online Raman Analyzer

Request Info / Quote Request Info / Quote

Product Highlights

Fast

Get data in seconds.

Intuitive

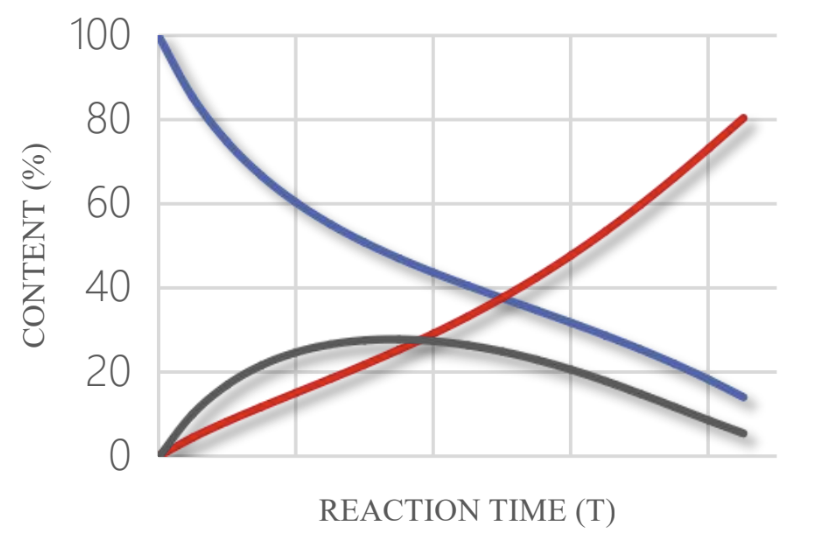

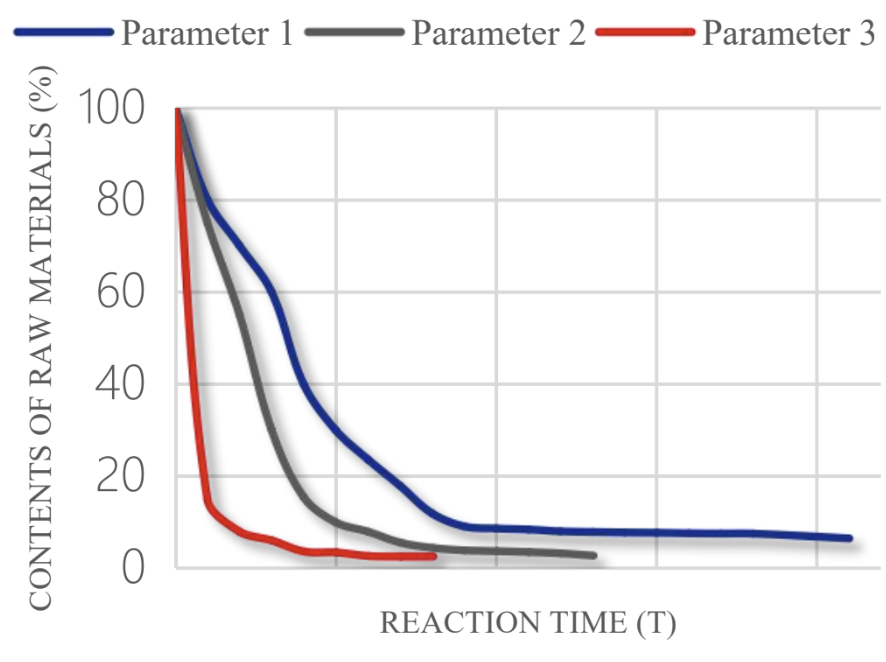

Display the latest dynamics of raw materials and products in real-time.

Multi-functional:

It can monitor the changes of multiple components and their contents simultaneously.

Universal

Several kinds of immersion probes are available, which are matched with different types of reactors. Flow cell is also designed with interfaces of different specifications to adapt to various kinds of continuous flow reactors.

Highly applicable:

It is applicable to scenarios with high temperature and high pressure, strong acid and alkali, and strong corrosive systems.

Intelligent:

An intelligent algorithm automatically analyzes spectrograms, and the database with 30,000+ data points assists in identifying system components.

Continuous monitoring of reaction process

Quick screening of process parameters

Product Specifications

| Application Mode | Immersion Probe  | Flow Cell  | Side Window  | |||

| Laser wavelength | 785nm and 1064nm (optional) | |||||

| Probe | 30 cm, customization supported | |||||

| Channel | Standard single channel, 1-4 channels are optional | |||||

| Immersion probe | Models: PR100, PR200 and PR300, which are matched with different reactors and reaction conditions | |||||

| Flow cell | Model: FC100, FC 200 and FC300, which are matched with various pipe connections and reaction conditions | |||||

| Window | Resistant to strong acid and alkali and applicable to such systems as for hydrofluoric acid | |||||

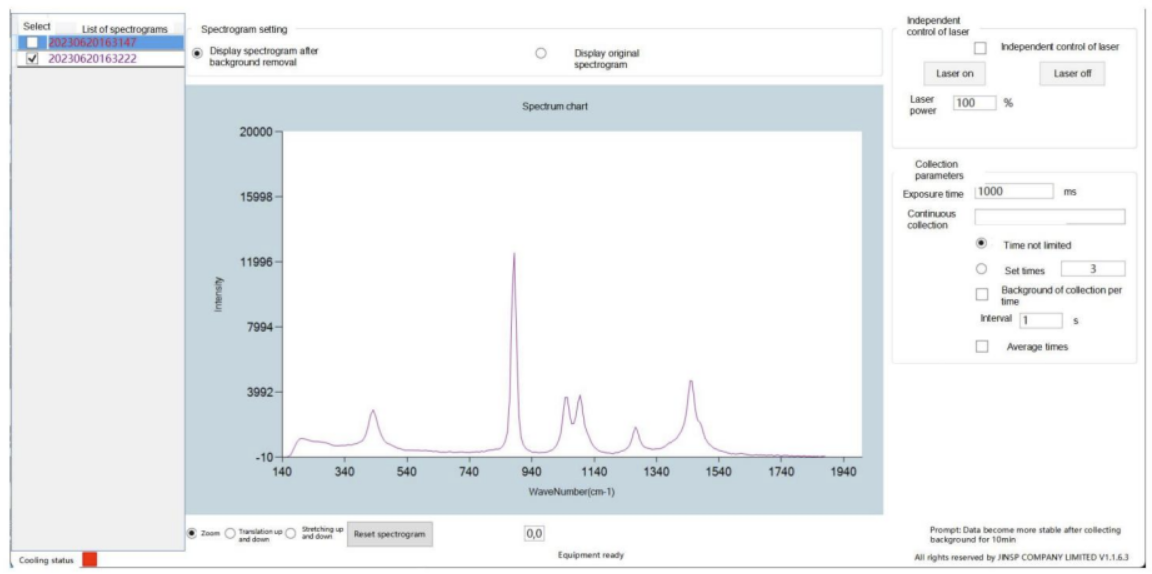

| Software functions | On-line monitoring, continuous data acquisition, data analysis, data comparison, method research, modeling, etc. | |||||

| Ambient environment | Working temperature: 0-40°C; storage temperature: -20-55°C | |||||

Usage Modes

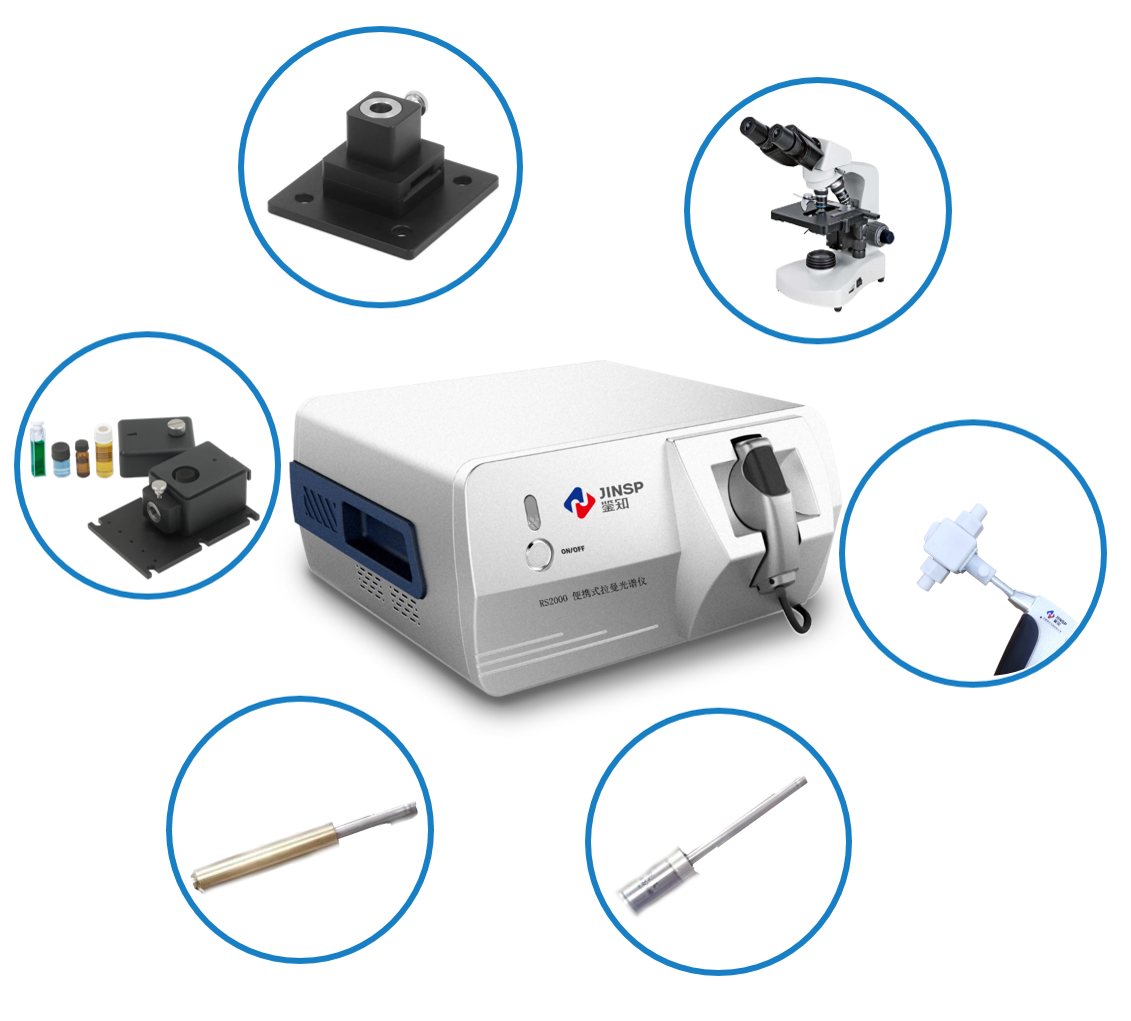

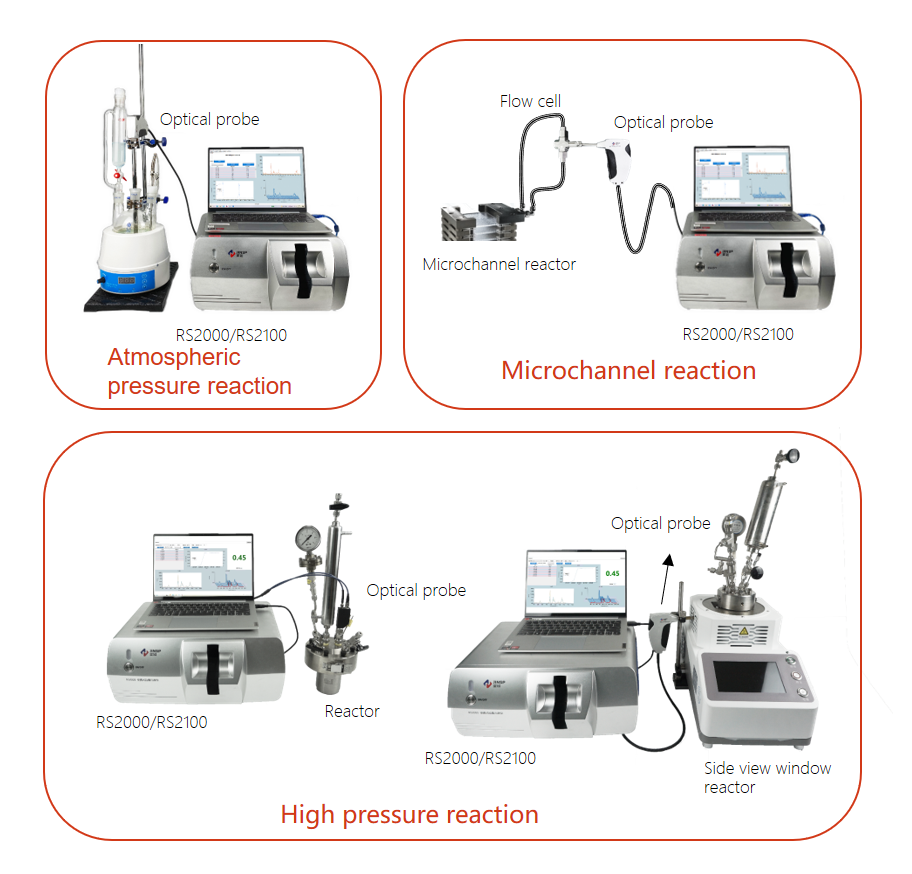

RS2000/RS2100 has three usage modes in the laboratory, and each mode requires different accessories.

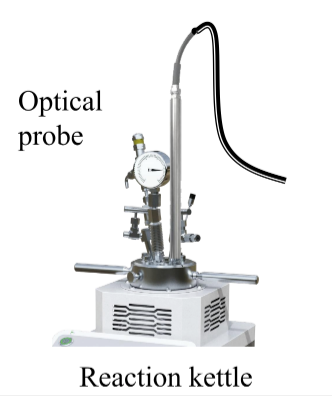

1. The first mode uses an immersed long probe that goes deep down to the liquid level of the reaction system to monitor each reaction component. Depending on the reaction vessel, reaction conditions, and system, different specifications of probes are configured.

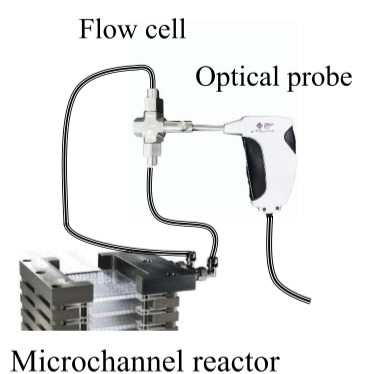

2. The second mode involves using a flow cell to connect a bypass probe for online monitoring, which is suitable for reactors like microchannel reactors. Various probes are configured based on the specific reaction vessel and conditions.

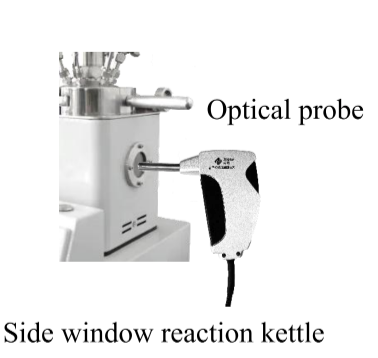

3. The third mode utilizes an optical probe directly aligned with the side window of the reaction vessel for reaction monitoring.

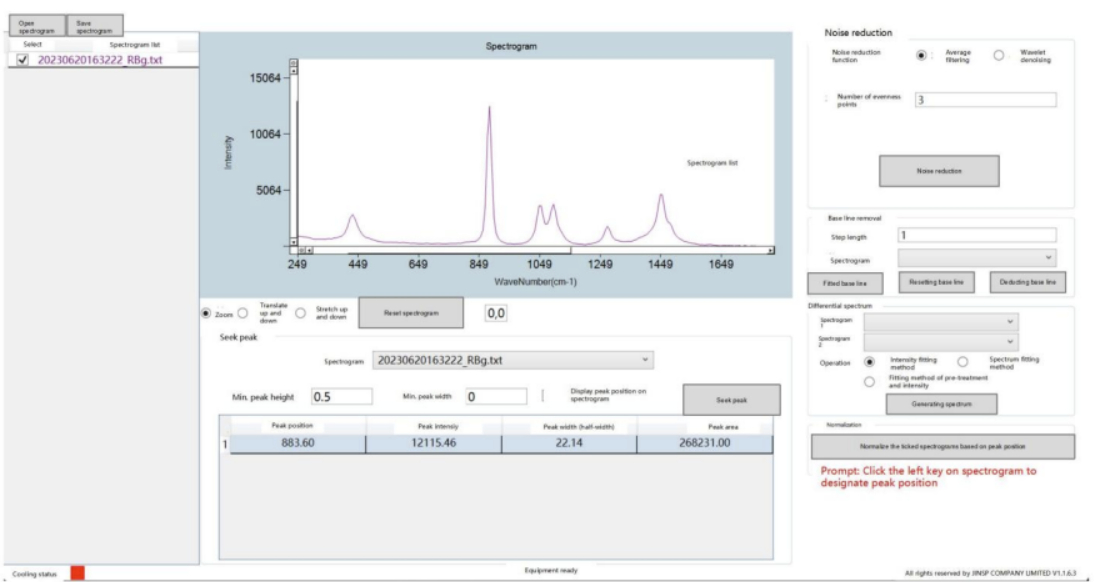

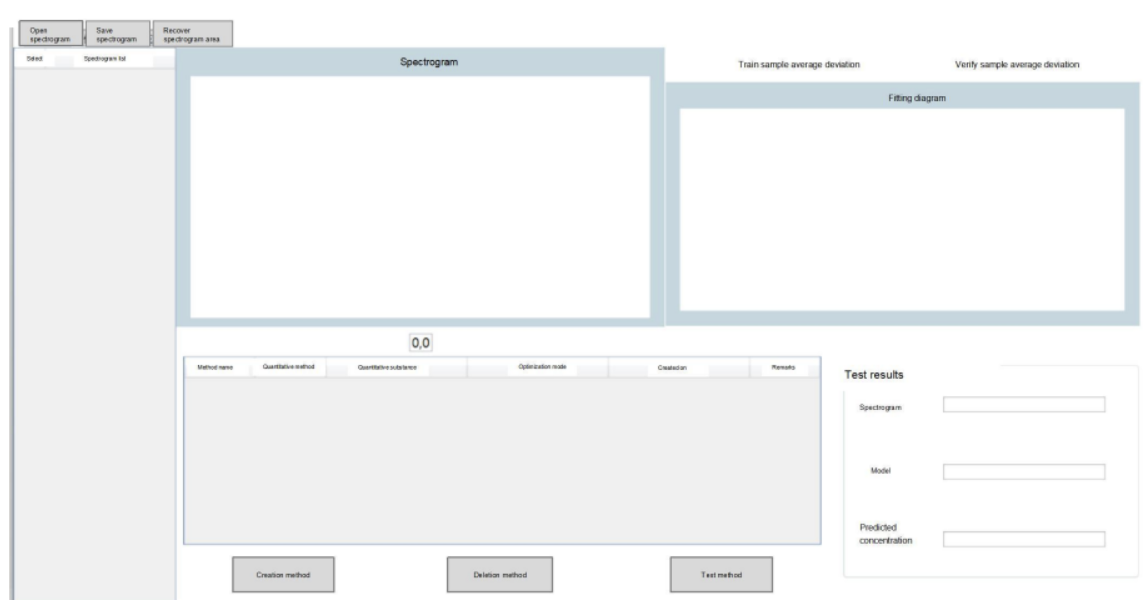

Software Functions

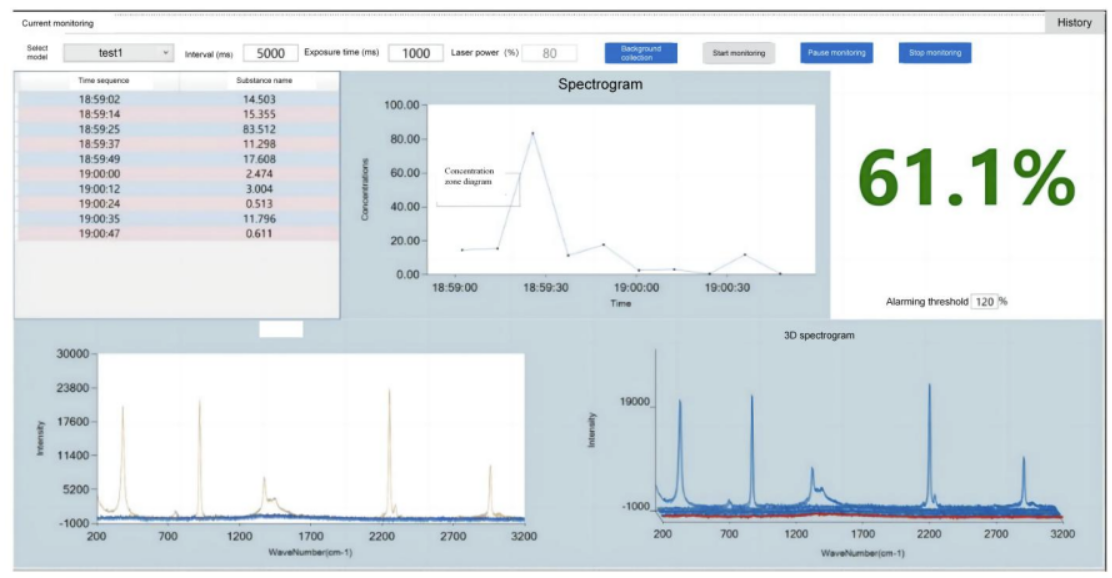

Online Monitoring

Data acquisition

Data Processing

Research Methods

Li-ion battery industry:

Research on the synthesis process of bis(fluorosulfonyl)amide

Biopharmaceutical industry

Drug crystal form research and consistency evaluation

Quality Control in Biofermentation Engineering

Fine chemical industry News

Research on the process of producing furfuryl alcohol by hydrogenation reaction of furfural

Process control of bioenzyme catalytic reactions of nitrile compounds

A certain ultra-low temperature nitrification reaction

Research on o-xylene nitration reaction process

.... and more

Related Products

|  |  | ||||

| Model | RS2000 | RS2000A | RS2000T | RS2000TA | RS2100 | RS2100H |

| Features | High sensitivity | Cost-effective | High sensitivity | Cost-effective | High applicability | High applicability, high sensitivity |

| Number of detection channels | 1, single channel | 1, single channel | 1, single channel | 1, single channel | 1, single channel | 1, single channel |

| Dimensions | 375 mm (width) × 360 mm (depth) × 185 mm (height) | 75 mm (width) × 360 mm (depth) × 185 mm (height) | 496 mm(width)× 312 mm(depth)× 185 mm(height) | 496 mm(width)× 312 mm(depth)× 185 mm(height) | 375 mm (width) × 360 mm (depth) × 185 mm (height) | 300 mm (width) × 356 mm (depth) × 185 mm (height) |

| Weight | ≤10 kg | |||||

| Probe | In standard configuration, one 1.3 m non-immersed fiber optic probe (PR100) and one 5 m immersed probe (PR200-HSGL), optional configurations include other probe models or flow cells. | |||||

| Software features | 1.Online Monitoring: Continuous real-time collection of single-channel signals, providing real-time substance content and trend changes, enabling intelligent analysis of unknown components during the reaction process, 2.Data Analysis: Capable of processing data through smoothing, peak finding, noise reduction, baseline subtraction, difference spectra, etc, .3.Model Establishment: establishes a quantitative model using known content samples and automatically builds a quantitative model based on real-time data collected during the reaction process. | |||||

| Wavelength accuracy | 0.2 nm | |||||

| Wavelength stability | 0.01 nm | |||||

| Connectivity interface | USB 2.0 | |||||

| Output Data format | spc standard spectrum, prn, txt and other formats are optional | |||||

| Power supply | 100 ~ 240 VAC,50 ~ 60 Hz | |||||

| Operating temperature | 0 ~ 40 ℃ | |||||

| Storage temperature | -20 ~ 55 ℃ | |||||

| %Relative humidity | 0~90%RH | |||||

| Power consumption | 50 W | |||||

| Pre-heating time | <5 min | |||||

| Communication protocols | Modbus | |||||